Pattern Making

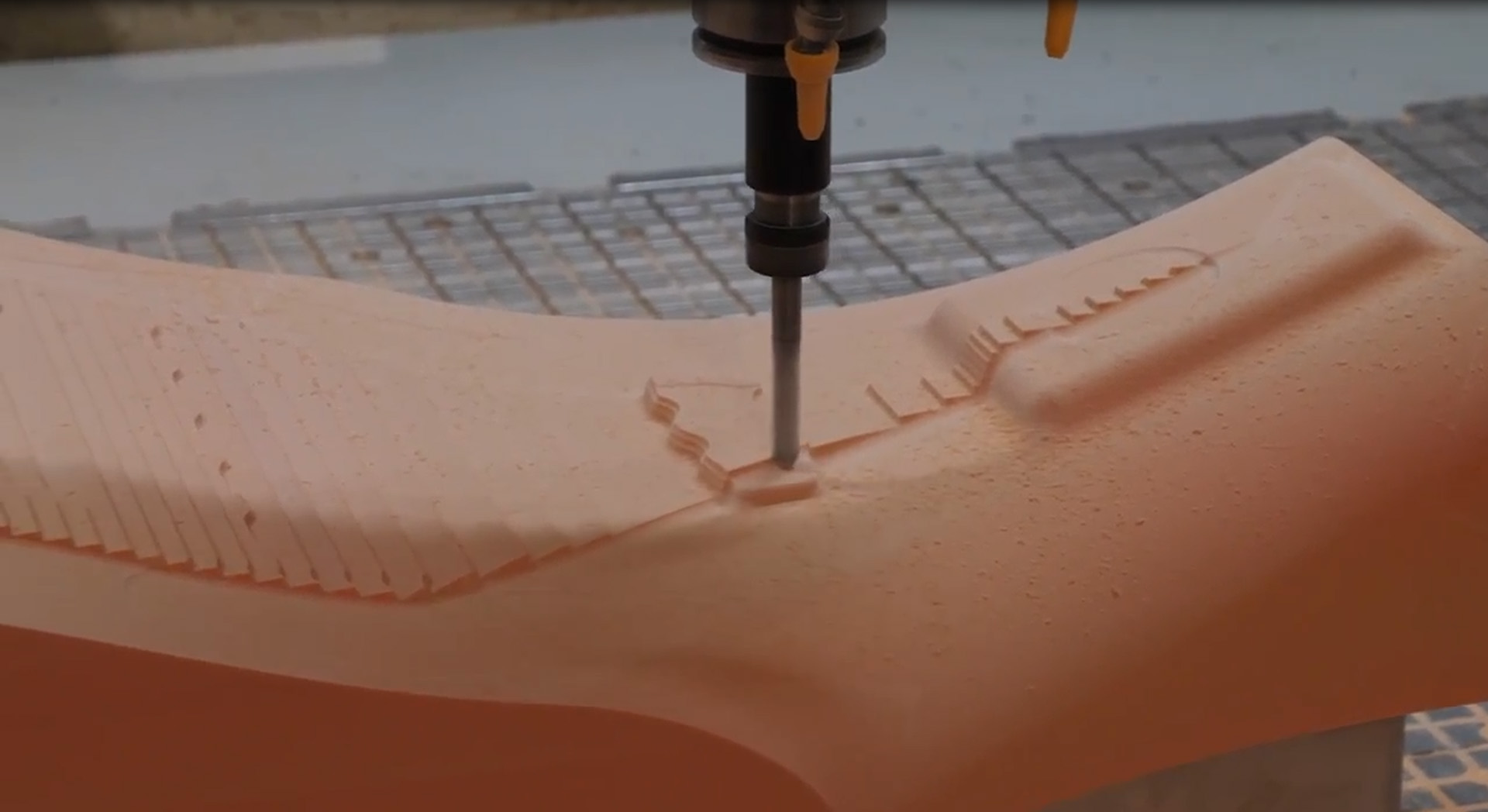

Aided by specialist CNC machinery and in particular our Belotti FLU 5 Axis machining centre and our 3D LASER scanner we are able to provide pattern tools quickly, efficiently and to a proven 100% accuracy.

Whilst we have always employed time served pattern makers our commitment to new technology and the very latest in machine centres give us that extra edge in the F1, automotive and aerospace sectors.

Our comprehensive approach to pattern making allows our clients to treat our production as an extension of their own facilities and coupled with our MIE Trak monitoring system we can indicate accurately delivery lead-times and performance compliance.

Born out of our pattern making is our ability to reverse engineer a product or a part where no CAD data exists or existing drawings maybe hard to decipher. Utilising our 3D LASER scanner we can plot the exact dimensions of a part or product and from this produce a 3-Dimensional CAD drawing and onwards to producing a pattern mould.

Once again, our investment in technology and the latest in machine centres gives clients the reassurance of 100% proven accuracy.

Restrictions of course apply in what we can demonstrate of our past work but below demonstrates well the process of engineering pattern making and the verification by 3D LASER scanning and onwards in this case to the mould tool producing a vacuum formed part 100% accurately.